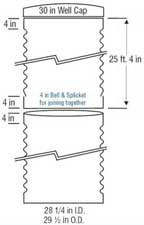

Corrugated Well Casing

"EXCEPTIONALLY STRONG" - see our SRC report"COMPARATIVELY LIGHT" - only 400 lbs. per length

Features

- Corrosion resistant

- Lightweight

- Corrugated for extra strength

- Reduced install time (up to 30%!)

- Well designed

- Economical

- Customer Perforation allows maximum water flow

- Incredible strength to weight ratio

- Only 400 lbs per length (25')

Why choose GP Fiberglass?

- We have been manufacturing corrugated well casing for over 20 years

- Accepted in North America as the industry standard

- Over 1 million feet of our well casing is in the ground across North America

These attributes make for easy work on any depth of well. GP Fiberglass has been building

corrugated well casing for over 20 years. A unique manufacturing method allows us to save time

and waste, giving you a consistent and reasonably priced well casing.

These attributes make for easy work on any depth of well. GP Fiberglass has been building

corrugated well casing for over 20 years. A unique manufacturing method allows us to save time

and waste, giving you a consistent and reasonably priced well casing.

More Information

Click here to view this products catalog page.

Installation

Click here to view some pictures of Reynolds Drilling Corp of Illinois installing some of our well casing.

Highlights

Hover over any of the highlighted areas to find out more about our casing.